Are you considering the planet when you’re purchasing your labels. point of sale or printed products?

With already 5 trillion pieces of plastic floating in our oceans, being more conscious of single use plastics can be incredibly important to solving the environmental crisis, especially since 73% of beach litter include items like bottles, cigarette butts, cheap shopping bags, food wrapping and sanitary products. All single use items. With the current war against COVID-19, single use surgical masks, test kits and bacterial wipes as fast becoming big problems too.

So why make your labels and POS part of the problem?

Before we get into products, materials and solutions let’s talk about the difference between biodegradable, compostable and recyclable.

Biodegradable:

This means that it can be naturally broken down by micro-organisms such as bacteria and fungi in certain conditions. Biodegradable products decompose much faster than the traditional materials which may take hundreds of years to fully breakdown.

Compostable:

Compostable products are made out of natural materials (like starch) and deteriorate into ‘compost’ without leaving behind any toxic residue when they break down. To be classed as compostable, products must meet specific requirements. Composting is a controlled process that typically happens in an industrial setting – compostable products are not suitable for home composting unless it has been certified as Home Compostable. It is important to check spec sheets and labelling to make sure the product is disposed of correctly.

Compostable and biodegradable plastics are not currently recyclable and can actually contaminate the recycling process. However, developments are happening which means that work is underway to create compostable products that are also recyclable.

Recyclable:

Recycling is a process of turning used materials into something new, which then keeps products away from landfill for longer. There is a limit in how many times some materials can be recycled; for example – plastic bottles and paper can usually be recycled a handful of times before they become unusable. Whereas others like glass, metal and aluminium can be endlessly recycled.

From recent surveys we can see that the Coronavirus pandemic has made a vast range of people become more ethical consumers. With sales in vegan food products soaring, organic fruit and veg becoming popular and clothes are becoming more sustainable; it makes perfect sense that the labelling and packaging that comes with them are also ethically sourced. Whether that being inks, materials, adhesives; talking to suppliers about more eco-conscious options isn’t as difficult as it sounds.

With how the world is changing and evolving, companies need to too. That’s why so many label and point of sale suppliers are making big steps to make eco-friendly products more accessible for even the smallest of businesses – from a simple design for a vegan soap company to intricate shelf edge strips to advertise an indie wine in a farm shop.

Like many companies – we are evolving too! Joining our card shelf point of sale items is a planet-friendly label. Produced from a Home Compostable material and paired with an eco-friendly adhesive, it’s a perfect alternative for your every day labels; and this is only the beginning for Customark, big steps are being taken to make sure we can provide you with labelling that is not only environmentally friendly but is friendly to your budget too.

Depending on what you want from your labels, either it being a white base label, clear or semi-gloss label. Both the white and clear materials are made from wood pulp, a sustainable raw material, and the semi-gloss is made from wood-free FSC certified printing paper. All materials come with an acrylic based permanent biodegradable and compostable adhesive. If you have an idea in mind why not talk to a member of our friendly team – our experience in the print industry is second to none.

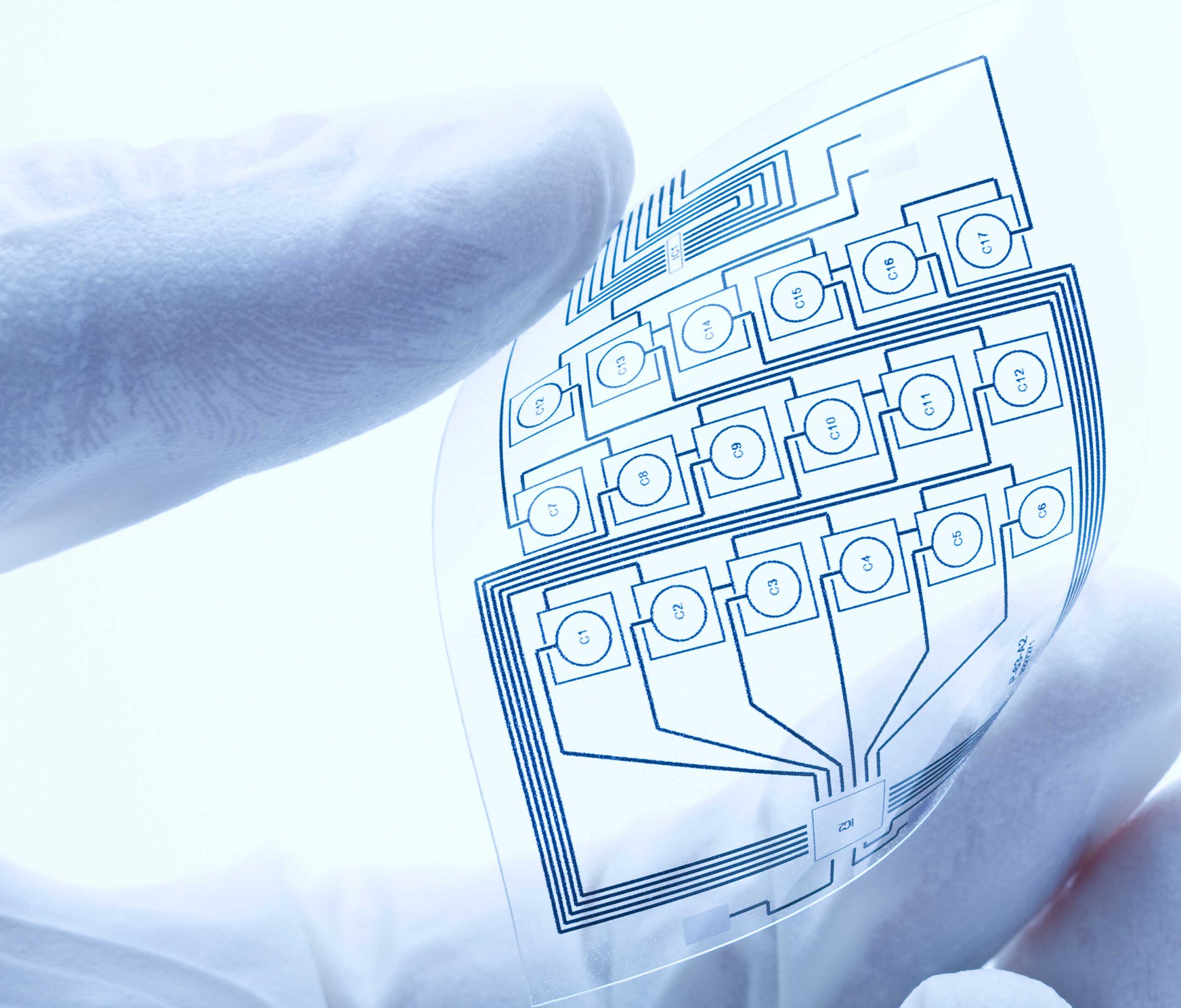

Our eco-friendly journey doesn’t just stop there – we’re even working on making our overlays and keypads too. Keep an eye out for more information on this soon!

We hope that this has helped you with making conscious decisions for your brand as well as the planet. For more information, please call 01384 264700 or email sales@customark.co.uk

Information sources:

- https://www.nationalgeographic.co.uk/10-shocking-facts-about-plastic

- https://www.macfarlanepackaging.com/blog/whats-the-difference-between-recyclable-biodegradable-and-compostable-packaging/