Reputed to be worth $73 Billion USD by 2025, the printed electronics market is growing exponentially. Printed electronics have been used in product design for decades and the impact of PE on everyday products design has been enormous. As an example, every Smartphone uses this technology as it is instrumental in the smart compact designs and incredible functionality. Without Printed Electronics we would still all be carrying around bricks for phones. According to Statista, that affects 3.3 Billion of us as 42.63% of the world population own a smart phone device.

Printed electronics

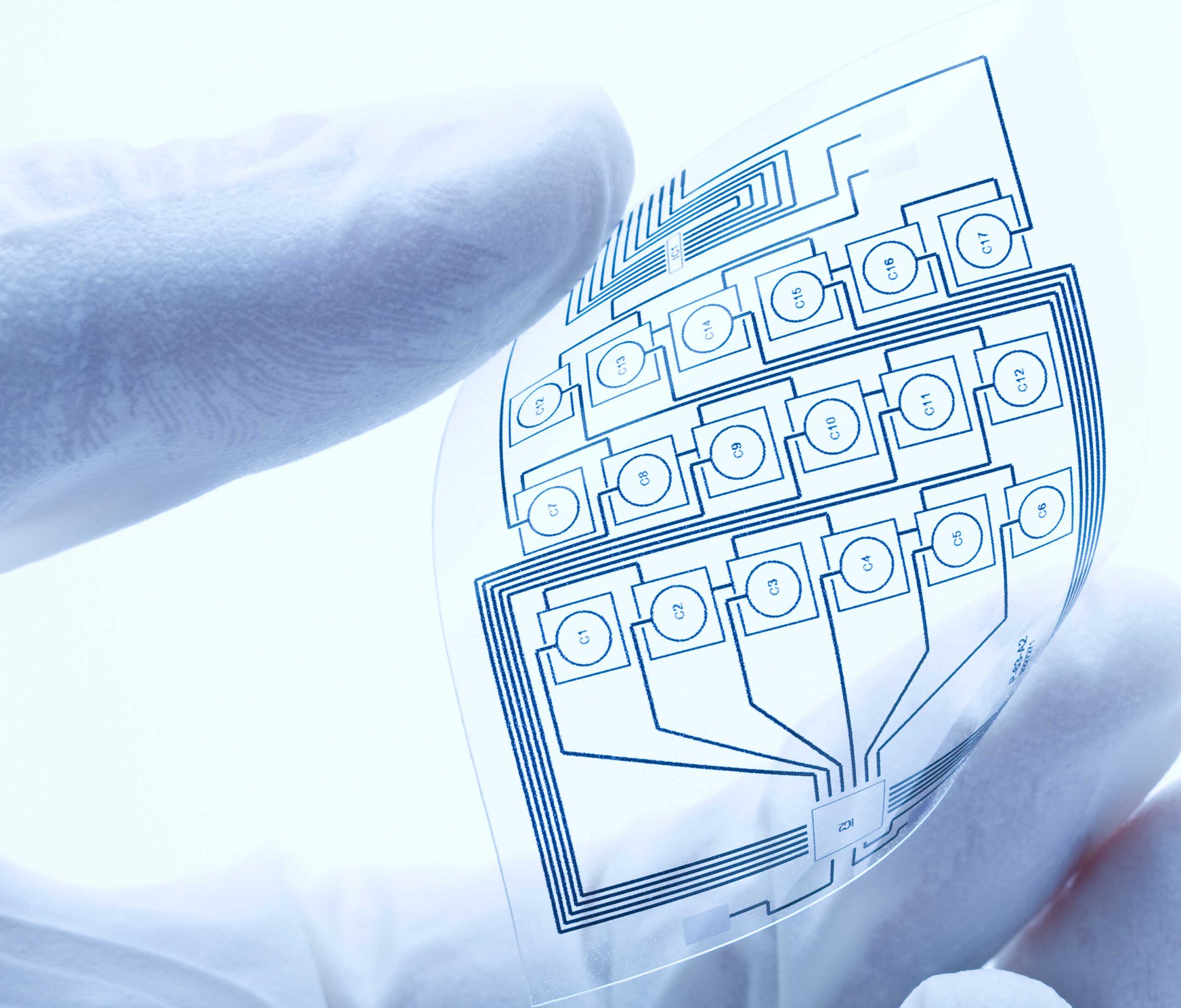

Is the application of conductive media onto a substrate. Usually flexible in nature but sometimes applied to solid surfaces. The ink can be made with carbon, Silver, gold or copper dependent on the application. Recent developments also allow for a clear conductive ink.

At Customark, we have been designing and printing electronic circuits since 1993 mainly circuits for membrane keypads and capacitive touch fascia’. The demand for this type of product or at least the membrane keypads has been around since the late eighties. The thin film, plug in connector nature of the products has steered fascia design since the late eighties. Originally, printed electronics related to plastic components that use one or more inks made of carbon-based compounds. As demand for thinner film electronics has increased, we see them in flexible keyboards, antennas and more. The process is usually as inexpensive as it is efficient and the expansive range of substrates and inks allows for selection of the correct film for the application.

This increased demand means that technological advancements in conductive inks and substrates are now significant. We generally use polyester as a substrate as it is extremely durable and recent developments also allow for significant forming to match complex geometry. To cope with the demands of durability and reliability the ink systems have also come a long way since the beginning. Allowing more flexibility without impairing conductivity.

All markets are affected by advances in the printed electronics market such as Defence, Healthcare, Consumer products, Media and of course IoT. IoT is a huge driver in increases in the use of PE. Home electronics and smart user interfaces take advantage of the technology in many forms such as capacitive touch fascia’ and flexible displays and allowing for more compact design as the markets demand.

Another huge contributor to the increased PE market is electronic wearables, smart clothing with embedded sensors, heating elements or smart glasses with integrated displays. All good examples of where we are now. This market should grow at an exponential rate in years to come with increasing demand for thin film flexible electronics. Smart clothing currently targets mostly the active market and sports professionals. However, most are now pursuing new markets in gaming, healthcare including care of the elderly which make a lot of sense. New market segments not only expand wearables market but expand the use of printed electronics technology worldwide.

One of the most recent new developments in the use of PE is In Mould Structured Electronics (IMSE) which is an advancement on in mould decoration, mainly used by the Automotive industry and consumer products. The printed electronics are placed in the cavity of the plastic injection mould tool so becoming an integral part of the finished moulding. The Automotive industry is significant in the growth of IMSE due to the attractive design, process efficiency and robustness of the finished components.

The final word. There is no doubt of the impact of printed electronics nor the importance of this technology in the hugely expansive electronics markets. Printed electronics are making everything better designed and smarter. From keypads and capacitive sensors to displays, printed electronics are being integrated into plastic film, fabric, and 3D printed objects. Printed electronics are opening a host of possibilities for electronic device applications and are influencing a range of industries including Automotive, Defence, Healthcare IoT and Wearables.